For a more comprehensive and up-to-date list of specs/info, please refer to: https://www.festo.com/nz/en/e/about-festo/research-and-development/bionic-learning-network/highlights-from-2018-to-2021/bionicsoftarm-id_68209/

Technical data

• Diameter: . . . . . . . . . . . . . . . . 80 mm

• Length of bellows segments: . . . . . 150 mm

• Length of rotary drives: . . . . . . . . 150 mm

• Maximum overall length: . . . . . . . .1050 mm

• Maximum degrees of freedom: . . . .up to 7

• Dead weight of bellows segments: . .500 g

• Dead weight of rotary drives: . . . . .750 g

• Working pressure: . . . . . . . . . . . up to 6 bar

• Repetition accuracy: . . . . . . . . . .5 mm

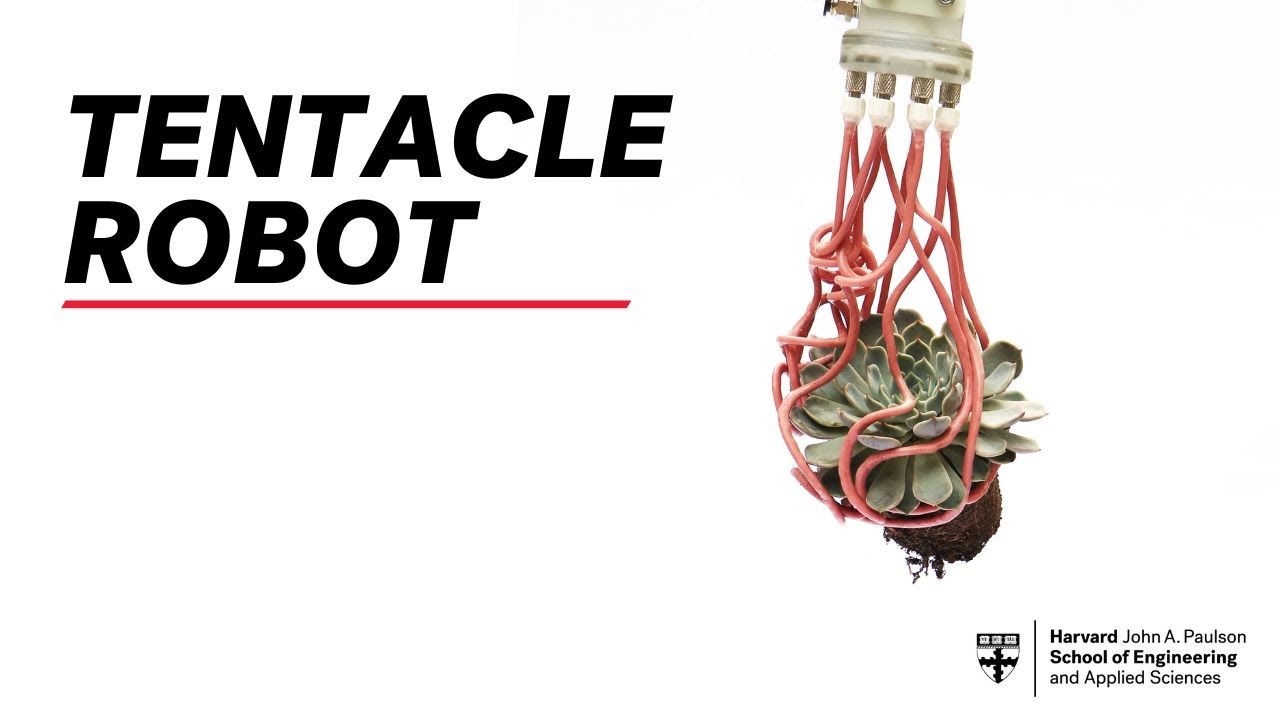

Modular system with a wide range of applications

The BionicSoftArm owes its flexibility to its modular design, which can be combined from several pneumatic bellows segments and rotary drives. Depending on the requirements, the length of the BionicSoftArm can be varied with up to seven pneumatic actuators, thus providing maximum flexibility in terms of range and mobility. This makes it very easy to implement applications that are difficult to realise with a standard robot.

The BionicSoftArm can work around obstacles even in the tightest of spaces. It can be used in direct human–robot collaboration as well as in classic SCARA applications – for example, pick & place tasks. The elimination of complex safety devices such as cages and light barriers shortens conversion times and thus enables flexible use at different locations – which is ideal for adaptive and economical production.

Natural role model and bionic predecessors

The Bionic Learning Network team has incorporated numerous findings and technologies from previous projects in the development of the BionicSoftArm. Like its two predecessors – the Bionic Handling Assistant and the BionicMotionRobot – the BionicSoftArm is inspired by the elephant’s trunk in its movements and functionality. With its pneumatic bellows structure, the BionicSoftArm effortlessly masters the flowing motion sequences of its natural role model.

Targeted motion dynamics thanks to 3D textile knitted fabric

The bellows are made of sturdy elastomer. Each one of them is covered with a special 3D textile knitted fabric consisting of two layers. A soft knitted fabric lies directly on the bellows to protect them from friction and wear. The high-strength fibres are oriented so that they allow the bellows structures to expand in the required direction of movement and at the same time limit this in the other directions. This new fibre technology is the key to unlocking the potential power of the kinematics as a whole.

Intuitive operation on a tablet

The software architecture of the BionicSoftArm also builds on previous projects of the Bionic Learning Network. The Robotic Suite provides intuitive operation. The graphical user interface was developed specifically for Festo’s bionic lightweight robots and was used for the first time in the BionicCobot . The user can easily teach the actions and set their parameters via a tablet.

Extremely precise movements thanks to digitised pneumatics

The commands are implemented by a Festo Motion Terminal VTEM, which is the essential element for control and regulation of the complex kinematics. The internal control algorithms of its motion apps and the installed piezo valves enable flow rates and pressures to be accurately metered and also varied as desired in several channels simultaneously. That enables both powerful and fast, as well as gentle and sensitive, motion sequences.

The interface between the tablet and the Festo Motion Terminal is provided by the ROS (Robot Operating System) open-source platform, which is used to calculate the paths for the kinematics. The ROS also interprets the incoming code from the tablet and forwards the resulting axis coordinates to the Motion Terminal.

FESTO

FESTO

Research

Research  Industrial

Industrial  Consumer

Consumer  Social

Social  Service

Service  Assistive

Assistive  Medical & Healthcare

Medical & Healthcare  Emergency Response

Emergency Response  Building & Construction

Building & Construction  Other Infrastructure

Other Infrastructure  Transport

Transport  Arts & Entertainment

Arts & Entertainment  Agriculture & Forestry

Agriculture & Forestry  Law & Order / Security

Law & Order / Security  Other

Other

Multi/General-Purpose Robots

Multi/General-Purpose Robots  View All

View All  Linkedin

Linkedin in Sydney, Australia.

in Sydney, Australia.

Share